|

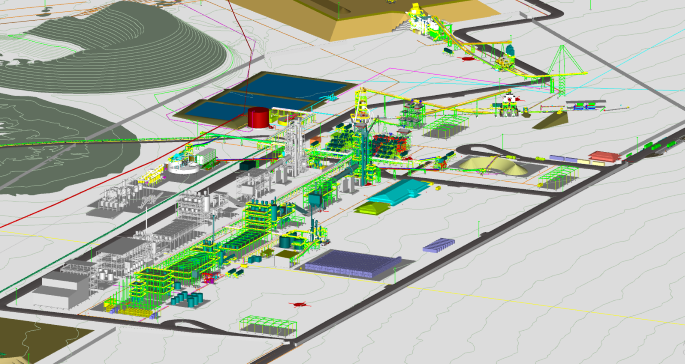

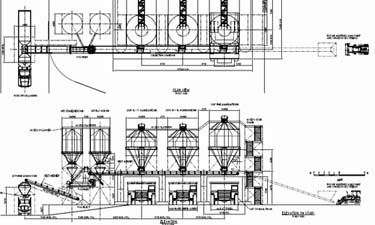

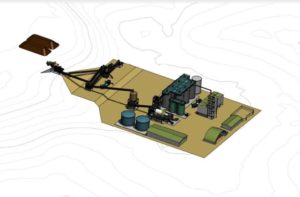

Kingston Resources – Misima Gold Project

Service: Pre-Feasibility Study for the complete Process Plant and Infrastructures

Mincore has been awarded the PFS for a 5.5Mtpa Process Plant and Infrastructure which will produce 150,000 Oz of gold per year for at least 15 years. A former plant owned by Placer has already produced 3.7Moz from 1989 to 2004. Dore produced will contain gold and silver.

Highlights: Mincore will leverage its experience in Papua New-Guinea to get quotation for civil, SMP and E&I contracts and Australian and South-East Asian suppliers for key equipment. Placer’s original plant will be replicated as much as possible as requested by the Client. Scope includes a comminution circuit, leaching, CIL, detoxification, acid wash, elution and refining as well as a power plant and port rehabilitation. The PFS is expected to be done in 12 weeks and the CAPEX, OPEX and cashflow estimate to be ±25% accurate.

|

|

Fosterville Gold Mine FGM – Samplers Upgrade

Service: Mincore has completed the Design, Supply, Construct and Commissioning of automatic samplers into 7 locations around the process plant mainly are Cyclone Overflow, Flotation Tails, Neutralisation Tails, BIOX FeeCyanide Destruct Tails, CIL Tails and Flash Flotation Concentrate.

Mincore assisted FGM by delivering fast tracked design, procurement and construction services, including:

- Front end and detailed engineering of the long lead items.

- Client 15%, 30% and 70% Design Reviews to lock down design with end-user at an early stage

- Consideration to surrounding installations tie-ins.

- Underground & aboveground piping.

- Multiple work-fronts opened at the same time in strict accordance with safest methodologies

- Off-site pre-assembly at Vendor’s workshop optimised

- Hazop performed and actions

|

|

Red River Resources – Gravity Circuit Design for Hillgrove Gold Mine

Service: Mincore is engaged in the Design and Engineering of a Gravity Circuit to remove free ‘gravity recoverable gold’ from the Baker’s Creek Mine gold ore dump at Hillgrove Mine Site.

Highlights: The Hillgrove Mine site includes a 250ktpa capacity processing plant currently comprising a selective flotation circuit (capable of producing antimony-gold and refractory gold concentrates), an antimony leach/SXEW/refining & casting plant, a gold cyanide leach circuit & gold room and a pressure oxidation circuit. Current testwork has indicated that 61% of the gold in the Baker’s Creek Mine ore dump will be recovered by gravity. The gravity circuit will be bolted onto the existing grinding circuit to treat the gravity recoverable gold. The gravity circuit is expected to treat 300ktpa of ore with an average gold grade of 2.7 g/t.

|

|

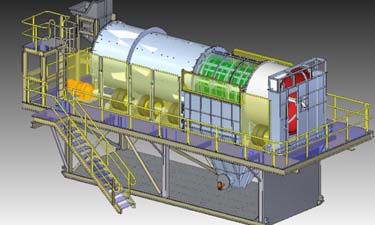

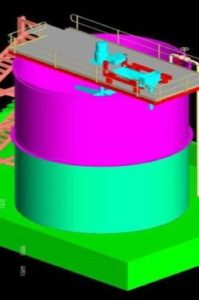

Fosterville Gold Mine FGM – Gold Room Upgrade

Service: Mincore has completed the Design, Supply, Construct and Commissioning of Gold Room Upgrade, Carbon Regeneration Kiln and Elution Circuit.

Mincore assisted FGM by delivering fast tracked design, procurement and construction services, including

- Front end and detailed engineering of the long lead items.

- Client 15%, 30% and 70% Design Reviews to lock down design with end-user at an early stage

- Consideration to surrounding installations tie-ins.

- Underground & aboveground piping.

- Multiple work-fronts opened at the same time in strict accordance with safest methodologies

- Off-site pre-assembly at Vendor’s workshop optimised

- Hazop performed and actions

Highlights: The original processing plant was commissioned in 2005 and is processing gold ore to produce dore bullions. Approximately 620,000 oz of gold production was recorded in 2019. With continued exploration success and a higher forecast of gold production expected to be treated, Fosterville Gold Mine have upgraded its processing facilities to cater for the increased throughput. Upgrades included a 500kg/h Carbon Regeneration circuit, 2 off 3.25T Pressure Zadra Stripping circuits and a new air-conditioned double storey Gold Room capable of smelting both gravity recoverable and EWC sludge gold using 2 off A300 Induction Furnaces.

|

|

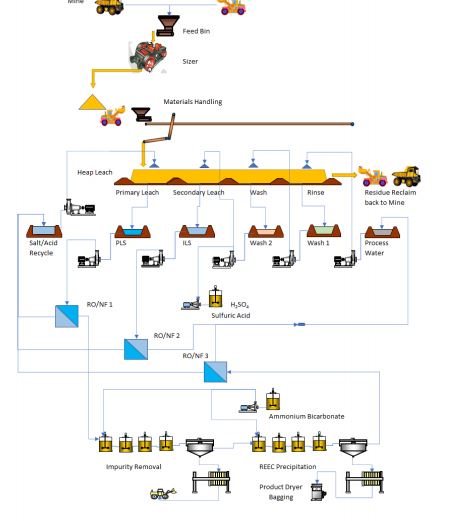

Lane Xang Minerals Limited Copper Mine LXML –Detailed Design, Construction Support and Commissioning of Pilot Plant Heap Leach Facility

Service: Mincore has completed the detailed engineering design and drafting including engineering management required to install a fully operational pilot plant heap leach facility at the Sepon copper mine in Laos. |

|

BCM Investments – Poura Gold Mine Feasibility Study

Service:Tails Reprocessing, Poura Open Pits and Mining Approval

Mincore is engaged to support BCM Investments with mining development on the processing, water and waste management areas. Mincore has completed a scoping study for the tailings project in 2018 and the overall project schedule is estimated to be 12 months. |

|

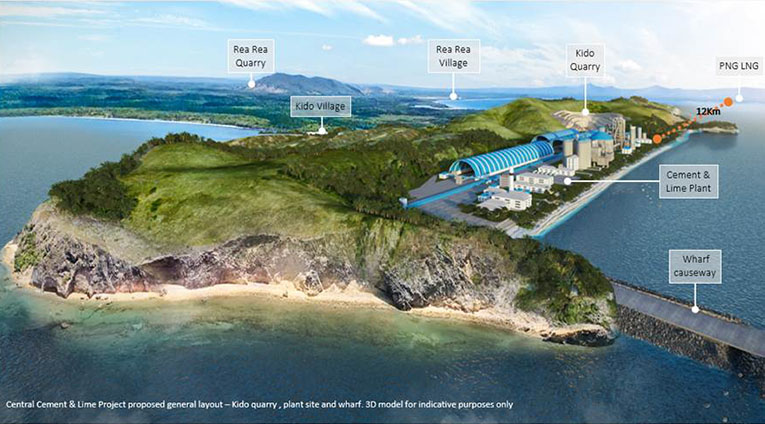

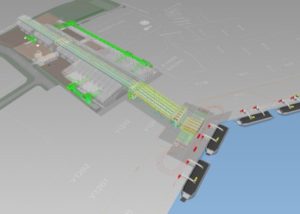

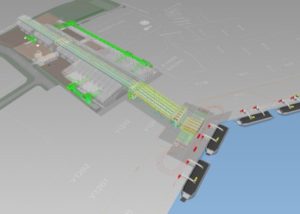

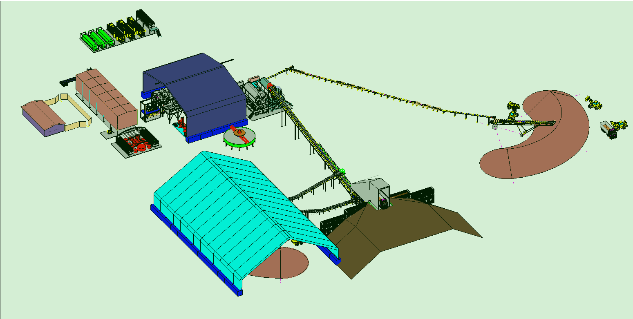

Arup- Jurong Port RMC Project Singapore

Service: Material Handling Equipment Consultant

Mincore developed concept for RMC material handling and storage facility at Jurong Port, detailed engineering and design of the approved layout, development of construction tender package for material handling equipment and site supervision during construction works.

Highlights: Mincore design team relocated to Singapore to help kick off the Concept Design stage and work closely with the Client to progress the design and meet the aggressive Project timeline.

|

|

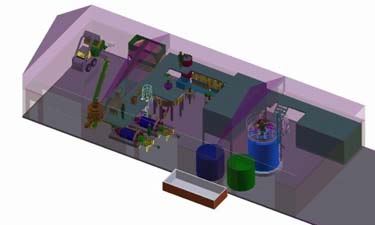

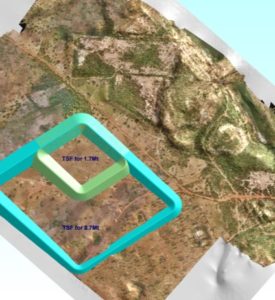

Mineral Hill Gold Mine – Mineral Hill Gold Mine Restart

Service:TSF Reclaim System Design, Plant Control System Design, MCC, Prep Tank, CIL Thickening, CCCW Area, Oxygen Generation & Injection, Detox Thickening

Highlights: Mincore has been engaged to deliver eight work packages for the re-start of the Mineral Hill Gold Mine in Condobolin, NSW. The plant will re-treat the tailings from the tailings storage facility, for a duration of approximately two years. The re-start requires the plant to be reconfigured to treat the tailings, accordingly, there are six new equipment packages to be designed, fabricated, installed and commissioned.

|

|

K92 Mining – Kainantu Gold – 1MTPA Expansion Project

Service:PEA Study for the new standalone 1MTPA Process Plant and associated Infrastructure for the planned Kainantu Gold Mine Expansion

Highlights: Mincore designed conventional flotation-gravity processing plant including:

- Single Stage Jaw Crusher (200tph)

- Direct feed to SAG milling circuit (125tph)

- Gravity Concentration

- Flash Flotation

- Rougher-Scavenger, Cleaner, Re-Cleaner Flotation Cells

- Concentrate Filtration and Drying

- Associated Infrastructure

|

|

Christian Pfeiffer – Conveyor design & Supply package for Boral Cement Facility, Geelong

Service:Mincore provided services to Christian Pfeiffer for the Engineering, Design, and Supply of various conveyors packages for Boral, Geelong Cement Grinding Facility.

Highlights: Mincore has provided a Design, Integration and Supply for the various Conveyor Packages that is in full compliance with Boral Specifications and Local Regulations.

Mincore offered low cost proven conveyor modules with prequalified robust equipment.

Standardisation of equipment across all the conveyor packages.

|

|

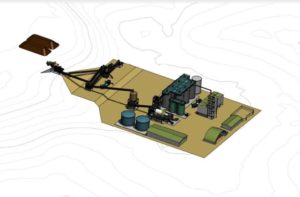

Investigator Resources – Paris Silver Project

Service: Mincore completed a Scoping Study, based on a number of process options tested, with sufficient Capex and Opex cost accuracy for Investigator Resources to make a Preliminary Economic Analysis (PEA), and determine the best Way Forward for the Project. We also carried out a Surface Infrastructure |

| |

|

|

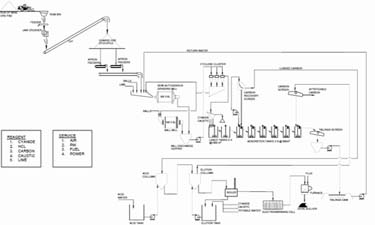

Lane Xang Minerals Limited Copper Mine LXML – Sepon Primary Gold Restart

Service:Mincore has completed detailed deisgn and construction support for the modifications and refurbishment of the Oxide Gold Plant at Sepon mine in Laos. Mincore was engaged for all disciplines to assess existing equipment and installations, prepare detail design drawings, review vendor data and provide procurement support for the project.

Highlights: The restart of the Gold Plant to process Oxide and Primary Gold includes the refurbishment and modifications of existing CIL circuits, LPA compressor system, HCl reagent system and the implementation of a new Mercury removal and recovery system.

The new Mercury management system was done to ensure that the future primary gold operation comply and LXML emission standards.

Mincore completed and delivered of twelve construction work packages to support the operational readiness of the Gold Plant to process Primary and Oxide ore.

Mincore integrated new dew design of CIL circuit, LPA compressors, HCl reagent system and mercury management system into an existing operating plant.

|

|

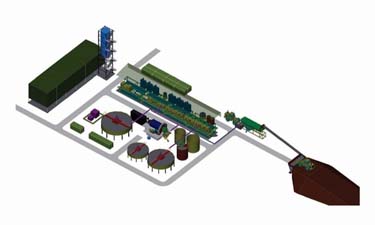

Singapore MHE Ready Mixed Concrete Facility

Service: Engineering Procurement & Construction Support

Mincore was awarded the Engineering for the Materials Handling Equipment MHE for a 10MTPA Receival, storage and reclaim system for a Singapore Port.

The scope included 40 conveyors, tripper distribution and FEL reclaim systems. |

|

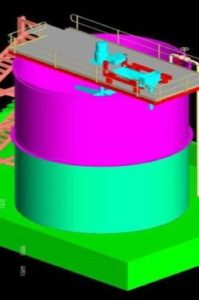

Arete Capital – Stawell Gold Mines (Gold)

Plant Refurbishment and Restart

Service: Engineering Procurement & Construction Serv

Mincore was awarded the Engineering, Procurement, Construction and Commissioning Management package.

The scope included complete plant refurbishment including 12 new 304ss CIL tanks.

The project was undertaken on a fast track basis with the complete EPCM phase performed in 7 months, enabling the plant completion and first gold in January 2019. |

|

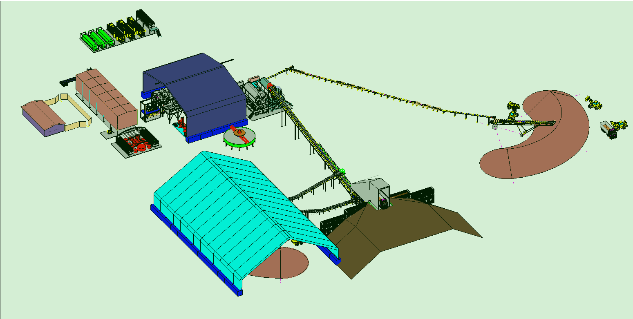

Bassari Makabingui Gold Project

Service: Engineering Procurement & Construction

Mincore is completing the Eengineering Procurement and Construction for the Hard Rock Open Pit Processing Plant, including detailed engineering, procurement and construction for the 300ktpa gold plant located in Senegal. Refer to factsheets for full project details |

| |

|

|

K92 Kainantu Gravity Gold Project

Service: Engineering Procurement & Construction Management

Mincore has completed the design and supply of a Gravity Recoverable Gold Circuit for the Kora Ore body. The gravity circuit consists of a Sizing screen, Sepro Falcon Concentrator, full security enclosed gold room including Holman Table, Calcine Oven and Barring Furnace. |

|

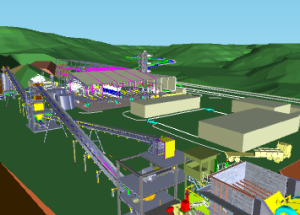

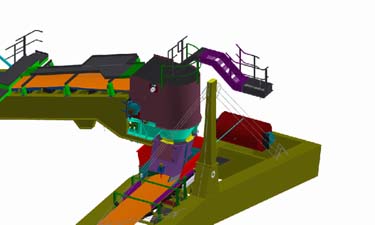

K92 Kainantu 400ktpa Expansion Project

Service: Engineering Procurement & Construction Management

Mincore is completion the design and supply of a new crushing plant, flotation plant and mill upgrades to expand the plant capacity from 200tpka to 400ktpa. The project is due for commissioning Q3, 2019. |

|

Datascience – Mincore

Sign an MOU for Project Collaboration

Service: Business Optimisation

Datascience and Mincore has signed an MOU to work in a collaborative manner to build a business optimisation services, centered on clients with Operational plants who want to achieve Worlds Best Practice. |

|

Bassari Resources – Makabingui Project (Gold)

Service: Engineering Procurement and Construction

Mincore has been awarded the Procurement and Construction Management for the Makabingui Gold Project, located in Senegal. |

|

RioTinto Alcan – Gove (Bauxite)

Export System Upgrade

Service: Engineering

Mincore was awarded the Engineering Package to increase the outloading rate by 30% from stockyard to shiploader. Construction work scheduled to be completed Dec 2017 |

|

RioTinto Alcan – Gove (Bauxite)

Supplementary Overland Addition

Service: Engineering and Construction Support

Mincore completed the completed multi-discipline design for a new Overland Conveyor feed system. The system included front end loader feed hopper, 40m long conveyor, transfer chute and retractable skirts on existing Overland conveyor 6-4. |

|

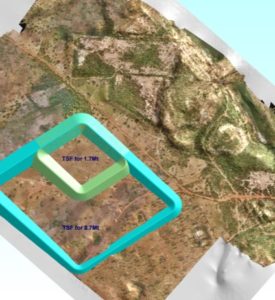

Evolution Mining (Gold)

Cowal Gold

Service: Feasibility Study

Mincore has been awarded engineering partner for the Life of Mine Feasibility Study. Mincore’s role is to provide feasibility level studies for tailings, explosive magazine and electrical upgrades. |

|

RioTinto Alcan – Weipa (Bauxite)

26A14 Chute Upgrade

Service: Engineering & Construction Support

Mincore in conjunction with BMEA completed full multidiscipline detailed design of the 26A14 transfer chute and steelwork module to handle 30% higher flow and sticky ROM bauxite ore. |

|

Goodline – RioTinto Alcan – Gove (Bauxite)

Stacker Hose Reeler

Service: Engineering

Mincore has been awarded the Engineering Design for a Hose Reeler Trailer to be added to the existing Stacker at Gove.

The scope of services includes the full multi-discipline design of the trailer module, water supply and shop detailing. |

|

Aura Energy – Tiris Uranium Project

Service: Scoping Study

Mincore completed a Scoping Study Review of the Feed, Beneficiation and Preparation plant associated with the Tiris Uranium Project. Emphasis was on Options analysis, selection of least cost, value add option. |

|

NSW – Copper Cobalt PFS

Service: Preliminary Feasibility Study

Mincore completed a PFS Level Engineering Study for a Copper-Cobalt Project in South Australia. The capital cost was developed around a lean, low startup cost strategy using global suppliers from China, Thailand, Europe, Africa and Australia |

|

Hanson Quarries – Screenhouse Upgrade (Concrete Products)

Service: Engineering Procurement & Construction

Mincore was awarded a scoping study level review of the proposed HPA project in Victoria, Australia.

Mincore provided scoping study level capital costings and process review. |

|

Hill End Gold – High Purity Alumina (HPA)

Service: Scoping Study

Mincore was awarded a scoping study level review of the proposed HPA project in Victoria, Australia.

Mincore provided scoping study level capital costings and process review. |